Check out our latest products

![]()

Light Lens Lab has shared a new behind-the-scenes look at its ambitious project to create film emulsions using its brand new proprietary machinery and emulsion process.

Back in January , PetaPixel reported news of Chinese optics manufacturer Light Lens Lab’s intention to expand into film development with the release of brand new emulsions.

In an update to the saga, the company which is most known for its reproduction of cherished but discontinued lenses, Light Lens Lab has taken to its blog in a post titled Film Project Update II regarding the subject of automation in the progress of their film development.

Light Lens Lab shared that it has built proprietary automation machine units from scratch, allowing it to be fully self-sufficient and have full control over the creation and delivery of its high-end experimental film emulsion.

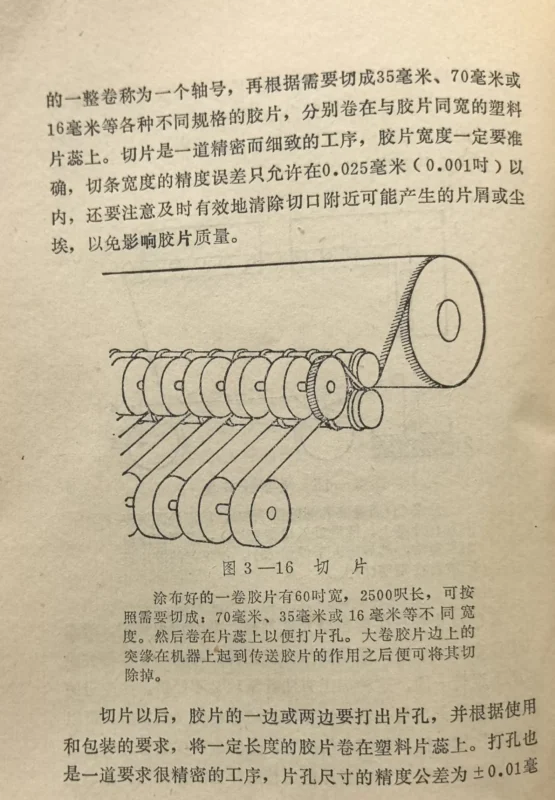

The company included several illustrations and behind-the-scenes looks at its new machinery, noting that while these pictures and demonstrations are done in daylight, the machines will be used in a fully light-tight environment once in production.

It is currently testing its automatic film rollers in 120 and 35mm format with machines designed for low-scale film finishing and packaging. The company aims to have the first batch of black and white emulsion completed by the end of 2025.

Additionally, Light Lens Lab says it is “developing an automatic high-speed film perforator for finishing perforated films in both photographic and cinematic format.”

The company included a video showing the film perforator in operation, practicing on a blank roll as well as a scrapped 70mm film roll.

The company is also researching and working towards the development of an automatic film emulsion coater which will enable it to produce master rolls of black and white film at a low volume, as well as an automatic variable-width master roll slitter, to pair with the emulsion coater and cut it’s master roles into various film formats.

With an intention to fully automate an entire production line for large format films in various formats, Light Lens Lab is also testing and developing a slitting, packaging, and encapsulating process. It expects the manufacturing facility to be ready for low capacity by the end of 2025, with plans to accommodate the introduction of peel-apart film.

Light Lens Lab plans to provide regular updates throughout the process, but this first look at its design and implementation of proprietary machinery and experimental film emulsion looks promising.

Image credits: Light Lens Lab

![[2025 Upgraded] Retractable Car Charger, SUPERONE 69W Car Phone Charger with Cables Fast Charging, Gifts for Men Women Car Accessories for iPhone 16 15 14 13 12, Samsung, Black](https://i1.wp.com/m.media-amazon.com/images/I/61SaegZpsSL._AC_SL1500_.jpg?w=300&resize=300,300&ssl=1)

![[True Military-Grade] Car Phone Holder【2024 Stronger Suction & Clip】 Universal Cell Phone Holder for Car Mount for Dashboard Windshield Air Vent Long Arm Cell Phone Car Mount Thick Case,Black](https://i2.wp.com/m.media-amazon.com/images/I/715PBCuJezL._AC_SL1500_.jpg?w=300&resize=300,300&ssl=1)

![[エレコム] スマホショルダー ショルダーストラップ 肩掛け ストラップホールシート付属 丸紐 8mm P-STSDH2R08](https://i3.wp.com/m.media-amazon.com/images/I/51BMFf06pxL._AC_SL1500_.jpg?w=300&resize=300,300&ssl=1)